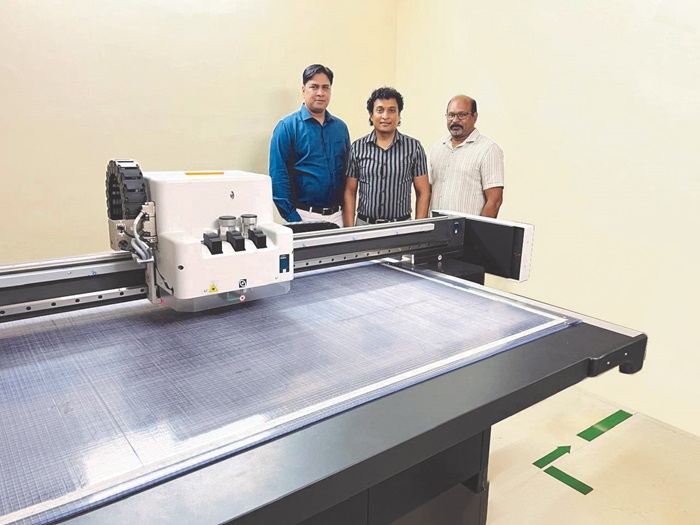

Leading Indian trade shop Veepee Graphic Solutions has added a second Kongsberg X20 cutting table to its Bangalore facility, with the new machine significantly boosting production speed and reducing waste to maximise productivity.

Mr Jaichandra, Managing Director, said, “The addition of the second Kongsberg table will not only supercharge production but also enable us to improve our offering for corrugated converters.”

He continued, “We are familiar with the capabilities of the Kongsberg X20 as we bought our first machine in 2018. We’ve been thoroughly impressed with the cutting table and Flexo kit, which enables us to finish all makes and thicknesses of plate with high precision. It has helped us to do away with the errors associated with manual plate cutting, and the bevel cut on thicker plates has helped our corrugated customers to drastically reduce print related wastage.”

“Using the Kongsberg X20, staggered finishing that would normally take anywhere from thirty to forty-five minutes by hand can be done accurately within three-to-five minutes,” he added. “Plates cut on the Kongsberg have also shown better print results for our customers. It helps reduce press bounce which means they can operate at higher speeds with reduced wastage, while right-first-time mounting brings further efficiencies throughout the run.”

He concluded, “The Kongsberg X20 fits in a truly tailored workflow,” he said. “It has seamless integration with the digital flexo software, which enables the customer to have ‘No Muda’ – or waste – while the iPC software, tooling options, and vacuum pump are specifically crafted to meet the production demands of plate cutting.”