At a time of significant change in the corrugated industry, GKD – Gebr. Kufferath AG and JKSP Services Ltd have confirmed a strategic partnership for the UK and Ireland. The companies say the partnership marks an important step towards increasing efficiency through innovative services and harmonised systems.

During the pandemic, the corrugated industry was focussing on performance in order to meet rising demand. However, in the last two years, the industry has been facing new challenges, partly due to the increase in raw material and energy prices. This development has led to a paradigm shift in the industry: Away from a pure performance and output orientation towards a more cost and energy efficient approach. The partnership between GKD and JKSP is a response to these market changes.

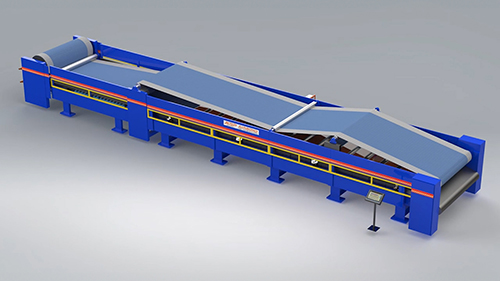

As a recognised sales and service partner in the UK, JKSP brings its expertise to the consulting and product optimisation process. In the product area, the JKSP AirBond System is particularly noteworthy, as it aims to improve the energy efficiency, board quality, reduce waste and improve the performance of corrugators – a characteristic that also distinguishes the BLUEBACKER corrugator belt from GKD.

An innovative aspect of the partnership is the new ‘Rotating Visits’ service model. In practice, this means that a JKSP service technician visits a customer’s plant twice a year to carry out a technical inspection of the condition of the corrugated board belts. This proactive service approach enables corrugated board manufacturers to make informed decisions about when a new belt should be purchased. Secondly, this approach helps to avoid long-term capital commitments and prevent the failure of production-critical elements.

Dominik Braun, Key Market Manager Corrugated & Pulp for Paper, GKD Group, says, “GKD and JKSP share the common goal of improving quality, service and efficiency in the corrugated board industry. The partnership shows how targeted cooperation and innovative solutions can be used to respond to changing market conditions across national borders – to the benefit of all.”

With the BLUEBACKER, GKD has developed a doublebacker belt for the corrugated industry that enables considerable savings in operating power thanks to its low weight per unit area. Its high air permeability also enables faster and more even vaporisation of the corrugated board. This enables customers to reduce the temperature of the heating plates and saves even more energy. Energy efficiency is also a key issue for JKSP. The British company has developed a system that ensures more efficient heat transfer and moisture removal in corrugators. When the JKSP AirBond system is fitted with the BLUEBACKER corrugator belt from GKD, the respective properties complement each other and provide a further boost in terms of performance and energy in the corrugated board industry.