What is one of the hottest growth markets in the printing industry today? Special effects and embellishments. As brands put more emphasis on enhancing their customer experiences and driving product revenue, leading printers have the foresight to equip their press operations with value-added offerings that offer a win-win for everyone involved. Brands are able to differentiate themselves from their competitors and get more brand appeal for their products, which translates into sales, while printers set themselves apart with unique capabilities. But to do this effectively requires automation and high throughput capabilities.

Behind this growth in embellishments and special effects is Koenig & Bauer. Its press features are linchpins to allowing printers to coat, embellish, and foil products inline with ease at high speeds.

“The luxury and boutique packaging market has been the driving force behind special effect printing for some time,” says Chris Travis, VP of Print Technology, Koenig & Bauer US. “But now it can be seen across the whole spectrum of all market segments. Its growth is based on the development of new consumables working in conjunction with custom press configurations. Printers are catering to customers who require a certain specific effect or need; some want to be flexible, others seek the ability to do multiple special effects, some need to heighten security, while others have designers who are creating new special effects.”

At Smyth Companies, one of America’s largest printing and packaging providers, innovation has always been one of the strengths of its business. Scott Fisher, President, Smyth Companies, says, “Our new Koenig & Bauer Rapida press provides us with a real edge over our competitors and helps us differentiate our business. Both Rapida presses are performing at optimum levels with additional embellishment capabilities. It pushes us to another level giving our customers a wide range of decoration options.”

So what has heightened the growth in specialty printing? Travis believes it is the ability to use special effect systems inline while the press is running at its highest maximum speed. “Special effect printing has been difficult to produce inline,” he says. “Printers had to use offline processes or put the job through two or more passes on press, and it was more of a challenge. But that didn’t hold printers away from seeing its potential as a value-added service. Press manufacturers like our company began to build new press configurations with multiple coating units where a lot of finishing could be accomplished inline.”

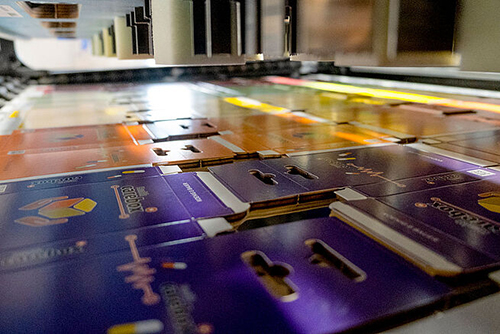

Koenig & Bauer offer presses with various coating configurations and has grown its decades-long reputation for producing customized presses for its customers. “If you can dream it, we can build it,” says Travis. “With our new generation of presses, we have revolutionized the production of special application presses up to 19 units with all processes integrated into one press in a single pass no matter the complexity. Unlimited varieties of configurations are available: coating units can be placed first or last, we can add multiple units like a double or triple coater, or two types of coating units at the end of the print job. Ultimately, our customers can create incredible effects such as matte, gloss, special colors, tactile and dimensional spot varnishes, cold foil and foilcure, metallic inks, embossing, die cutting, intricate folding, and cold foil applications.”

That’s been the benefit derived at the Carlson Print Group, a pioneer of specialty print products, packaging solutions, and finishing technologies. It has been utilizing its new Koenig & Bauer Rapida press to produce some of the most eye-popping customized print pieces for some of the most recognizable brands in the world. Carlson uses a wide array of specialty print and coatings techniques, such as its Cast n’ Cure, lenticular, texture/soft touch, motion coat, pearlescent, color foil, reticulating varnish, and Chrome FX. It offers extensive pattern options to add prisms of color on any print or packaging piece.

The latest features allow coating units to keep up with the high speed of the printing units. Travis explains, “Certainly, we differentiate from others due to the incredible speed we can change anilox rollers and plates. Our presses have the ability to change coating plates quickly and effectively. Operators can choose the correct anilox roller and our anilox revolver will put it in place without any tools or any human intervention. For ultra-fast makeready, we use pin register plates for the coating unit, which allows printers to dial in very accurate spot register.”

TPC Printing & Packaging uses its inline cold foil system on its new Rapida 105 PRO for about 50% of its work, which reduces its offline conventional hot foil stamping presses from running 24 hours/day to only running one shift per day.

“The world of embellishments and special effects is evolving and Koenig & Bauer will continue to play a significant role. Printers can expect new technology from Koenig & Bauer to continue explosive growth in the special effects industry. We look forward to introducing the many new configurations and options that can be created for amazing special effects,” concludes Travis.