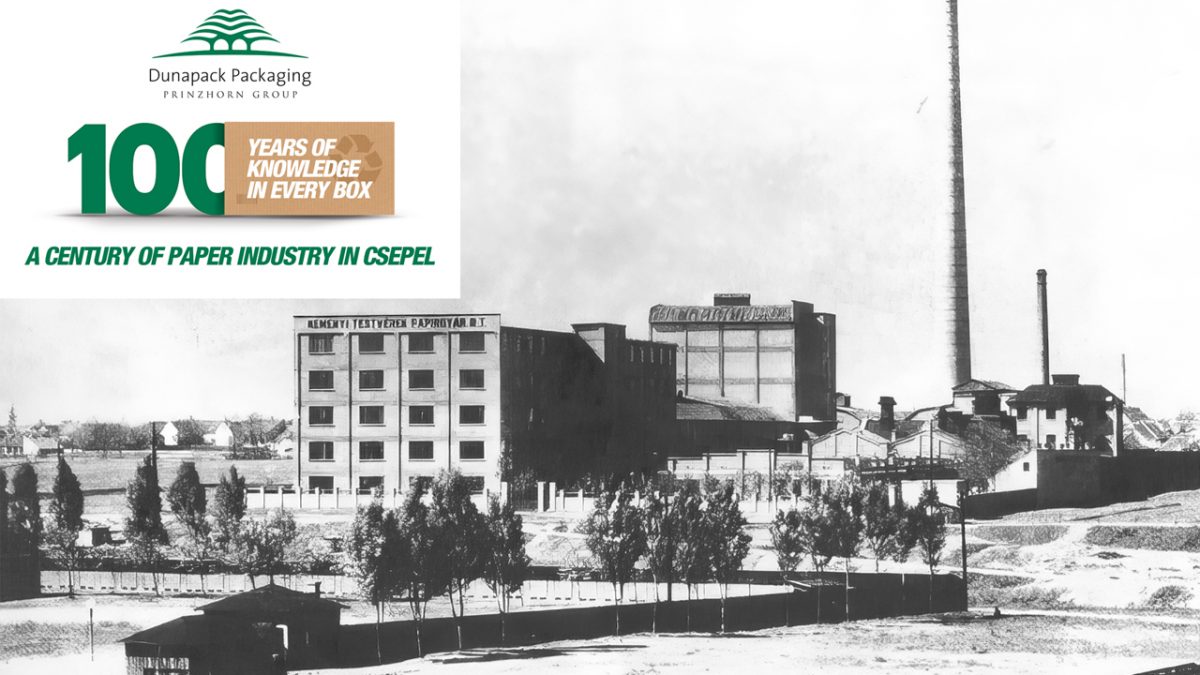

Budapest, the capital of Hungary, has a rich and diverse history that holds significant importance both regionally and internationally. Budapest’s history is marked by a series of transformations, from the Roman period to its role as a crossroads of cultures, empires, and political movements. Its rich architectural heritage, cultural contributions, and historic significance make Budapest a captivating and historically important city in Europe. And this year marks the 100th anniversary of a paper and packaging facility that was established on Csepel island on the bank of the Danube, on the south-western outskirts of the Hungarian capital.

“Since its foundation in 1923, our business in Hungary has grown and evolved, becoming a symbol of excellence in the field of corrugated packaging solutions,” says Dennis Belkovsky, Cluster Managing Director, Dunapack Packaging Hungary. “Our strongest competitive advantage is the service mindset, expertise and unwavering dedication of our Hungarian colleagues. Many of them have been in the company for 20-30 years and it is not unusual to see the several family generations working side by side.”

The paper and packaging business on the company’s site on Csepel island in Budapest started 100 years ago. Since then, this site continuously contributed to the overall success of the industry in Hungary. “We are market leaders today as well, and we strongly believe that this success will continue in the future,” adds Belkovsky.

Most Modern Technology

Dunapack Packaging operates three plants in Hungary, equipped with the most modern technology. They run three corrugators in Hungary, with machines from BHS Corrugated, Fosber and Mitsubishi. The newest corrugator is 2.8m Fosber S/Line that is able to run at 420 m/min.

On the converting side of the business, they have 22 lines in total in Hungary, mainly flatbed and rotary die-cutters from Bobst, with flexo folder gluers from both Bobst and EMBA. The plants are equipped with highly automated and efficient production machinery, internal logistic systems from Minda and NE Engineering and advanced IT solutions.

“Our Hungarian plants share a common customer database and having central planning in CPMS corrugated production management system from Witron, which helps us to balance the workload among the plants and provide reliable and flexible service to our more than 2,000 customers,” continues Illés Kurgyis, Operations Director. “Automatic palletisers, strappers and wrappers are installed from Mosca and Pamminger. In our newest plant in Dunavarsány, we also installed an automated tool storage from bcm transtech A/S. This automated, easy to use system houses all the printing plates and cutting dies, with robotic ‘pick and place’ handling.”

The Prinzhorn Group – who are the owners of Dunapack Packaging Division – has a longterm view on the business in Hungary and is constantly investing in the competitiveness of its Hungarian operations. “We continue investing into automation of our plants,” says Kurgyis. “In Csepel, our next step is the full automation of our intralogistics system from converting machines through to the finished goods warehouse.”

Well Accredited

As you would expect from a business with this depth of history, it comes as no surprise to see it conform to the latest industry standards and certification. Dunapack Packaging Hungary currently holds:

- ISO 9001, for Quality Management;

- ISO 14001, for Environment Management;

- ISO 45001, for Occupational Health & Safety management;

- FSSC 22000, for Food safety management;

- ISO 28000, for Security management;

- FSC for paper raw material from Forest Stewardship Council;

- Ecovadis assessment.

Dedicated Workforce

“Many of our employees have worked for Dunapack Packaging Hungary for decades, sometimes several generations of the same family work with us,” says Belkovsky. “This knowledge is special in the industry, and is one of our competitive strengths. We have to ensure that we pass on this knowledge to future generations.”

He continues, “We have a long history of creativity in packaging development. For example, in 2023 we won Worldstar Global Packaging Award 2023 in the ‘Transit’ category with a packaging solution for automotive glass roofs replacing wood and plastic-based packaging. This year, we won five awards at the Hungaropack Packaging Contest, including the main award for a special packaging for paraffin.”

Sustainability in Focus

The Csepel site is focusing on the production of innovative corrugated packaging solutions, using modern and energy-saving machines. “Overall, we use much less energy and water than before,” adds Kurgyis. “As a part of our ESG programme, all of our plants have modern waste water treatment units. We are currently working on installing a comprehensive energy measuring system and an intelligent building management system to reduce our carbon footprint and minimise energy consumption. We are also preparing for a solar panel installation.”

He continues, “Dunapack Packaging Hungary is a strong leg of our circular business model in Hungary. Recycled paper as the raw material has been used in our packaging factory in Csepel since the 1980s, and today the entire industrial cycle is being implemented in Hungary through the domestic subsidiaries of the Prinzhorn Group: among others, one of our sister companies, Hamburger Recycling Hungary Kft, collects the waste paper, and Hamburger Hungária in Dunaújváros produces 700,000 tonnes of corrugated paper from this – plus imported paper waste – every year, which Dunapack uses to produce state-of-the-art packaging solutions at our plants.”

Belkovsky concludes, “Our industry is a world champion in recycling; our products remain in circulation with a recycling rate and a content of recycled raw materials of around 90%. At Dunapack Packaging, we are proud to play a significant role in shaping the sustainable present and future in Hungary, especially as we celebrate the 100th anniversary of Csepel.”