Thimm Group has taken the next step in its digitalisation strategy and is investing €20m in a second digital printing system and associated peripheral works.

The HP PageWide T1195i Press is scheduled to be commissioned at the Alzey site in the first quarter of 2024. The new digital printing system is an important milestone for the packaging manufacturer in the digitalisation of its supply chains and in achieving the digitalisation vision of the ‘Internet of Packs’.

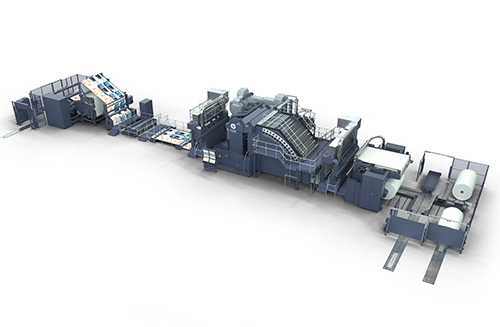

Following the successful launch of the first digital printing system in 2017 at Christiansen Print in Ilsenburg, Thimm Group has once again committed to the printing expertise of the manufacturer HP. Based on market requirements, the new digital web press capitalises on the development of the previous model and impresses with faster speeds and more production capacity along with an operating width of 2.8m. Innovative HP thermal inkjet print heads guarantee the system outputs a consistent print quality for sophisticated packaging designs, even at high speeds. To achieve this it has six different printing inks.

Kornelius Thimm, CEO, Thimm Group, considers the expansion of digital preprint as a complement to flexo-print to be a key competitive advantage. This is because in the current retail landscape, products must be available quickly and flexibly, customisable yet still cost-effective. This also has an impact on packaging management. He says, “In view of the increasing requirements of our customers, we have set ourselves big goals; no lead times for the production of packaging and displays, no MOQ, no additional costs in the supply chain and all within a sustainable manufacturing process. We have already achieved a great deal with our first digital printing system in Ilsenburg.”

For example, digital printing can be used to produce a wide variety of print images without any additional costs in the pre-press stage. Thanks to this print-on-demand production, resources are saved and unnecessary waste is avoided. Thimm has already reduced lead times by 75% and minimum order quantities by 90%. “We are taking a further decisive step ahead here with the second digital printing system. It will be positioned in our Alzey plant directly next to the existing corrugator. This will further reduce lead time by up to two days, as there will no longer be any need to move the printed rolls,” adds Thimm. In order to create space for the more than 50m long system, extensive preparatory measures for the installation are being implemented at the Alzey plant. Installation will then begin in the third quarter of 2023, with commissioning and inauguration planned for the Q1 2024.

With the acquisition of the second digital web press, Thimm Group is continuing to pursue its digitalisation strategy. Thimm adds, “We want to drive forward the digitalisation of the entire supply chain, including beyond the packaging industry. To do this, we need relevant data as well as digital and intelligently networked processes – from the printed paper roll through packaging production to retail and end consumers.”

Printed packaging acts as an information carrier because it is the only item that runs through the entire supply chain. At the heart of this vision is digital printing, which enables continuous codes to be printed in infinite numbers on the paper rolls. These codes provide relevant information at various points in the supply chain. For example, they control any further processing required on the paper at the machines in the packaging plant, provide data on the sale of the product or provide further information for end consumers as a QR code.

“Our digitalisation vision is the ‘Internet of Packs’ – meaning the networking of machines or objects in packaging management analogous to the Internet of Things. Each package has a unique code and can therefore be traced through the entire supply chain. The new digital printing system will bring us one decisive step closer to our vision,” concludes Thimm.