Sipack and Mauro Benedetti are both family companies, managed by people with a real passion for corrugated board.

On the day of the interview, Walter Pacioni, CEO of Sipack, was at Benedetti’s plant to verify the Acceptance Test of the Sipack Royal VB DD Flexographic Printer, which was installed recently. During this event, there were not only the testing technicians but also CEO of the company – Pacioni – who drives the passion and success for more than 25 years now.

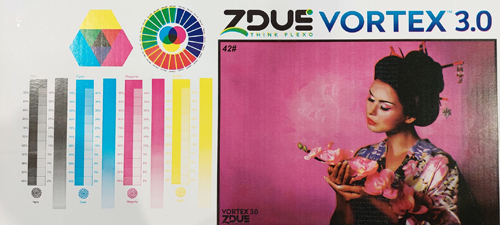

Factory Acceptance Tests can be a real challenge and the area around the machine becomes a hive of different colours, various types of board and lots of printing plates; then the counting of the lines, the machine speed, the verification of how the text is printed, the logos, the images, the cliché, until everyone is happy, then the desired results and to the words ‘printing test ok’.

Packaging Experts

The history of Mauro Benedetti is well known. The family has always been in the packaging sector; first as coopers repairing casks and barrels, then with wooden packaging and finally, thanks to Francesca Benedetti‘s father, Mauro Benedetti, during a study trip on corrugated board in Israel, he introduced this type of packaging to the family business.

From that moment, the production moved to Perugia, working mainly for a well-known company in the food sector, and only with corrugated packaging. Over the years, especially between the 1970s and 1980s, the company expanded its production plants, both in the south and in the north of Italy, to get closer to its customers. Following a family death in 2010, the company wanted to reshape the approach of business, returning to production concentrated on the primary site of Perugia, where they produce 90m sqm of board per year.

“In the last two years, we have never stopped the production,” explains Francesca Benedetti. “Food has been a growth sector, some non food companies have suffered a setback, but we have different types of customers and for this reason the plant was running all the time.”

She continues, “We have a wide range of products: American boxes, die-cut products and also fitments and accessories in corrugated board. We are living through years of transformation, with radical changes: consumer behaviours have changed, the choice of healthy foods, attention to the environment, plastic-free packaging, but also the creation of more comfortable home environments with energy saving, e-commerce and the development of family entertainment, a return to the essentials: a new lifestyle. Many companies have undertaken new challenges in Italy, thanks to economical and financing systems; companies have been encouraged to reinvest in their production sites, with new machinery and services. This has also happened to Mauro Benedetti; in fact the company has chosen to make changes to its production with the purchase of high-performance machinery, such as the Sipack’s flexographic printer.”

The Sipack Royal VB DD 12.21 flexographic printer installed at the Benedetti plant consists of five printing units, with vacuum transport from the feeder right through to the exit of the sheet, with preparation for the installation of UV dryers on each printing unit for instant drying. It is also provided with a transfer unit, but above all, with direct drive servomotors on each axis, maximum accuracy and economy in consumption of energy is ensured.

The Sipack Royal VB DD printer is a flexible machine, upgradable over time and suitable for optimising changeover times; in fact, with this machine, users do not necessarily need to change anilox rolls based on the board used, an important aspect for the efficiency; less downtime, less components to be replaced and less maintenance and labour. The fully controlled inking system and the automatic wash up allows the highest print quality and the minimum waste of ink and water – in short, a machine that takes care not only to the quality of the finished product, but also to the use of various board types.

The printer is in line with a flatbed die-cutter and is part of Mauro Benedetti’s corporate improvement strategy, along with other machinery recently purchased to respond to changing market demands.

“Business today means juggling between an increasingly changing demand, but above all being good administrators, with the increase in the costs of raw materials and energy; the stabilisation of the price requires a few more months – I understand the situation, because I also supervise costs and purchasing in the company. But I also think that the future is to drive green economy policies,” concludes Francesca Benedetti.