GPD Foodpackaging GmbH & Co. KG, headquartered in Bielefeld, Germany, manufacture packaging for food and, in particular, for frozen products. The plant is quite special and combines innovative technology with intelligent process optimisation to create a highly automated smart factory, furnished with its own logistics centre and direct motorway access.

At its brand-new and highly efficient Smart Factory in Rinteln, Lower Sayony, GDP has been producing food packaging on a grand scale since January 2022. This includes the production of 750m boxes for frozen pizza, which are processed on two MASTERFOLD 75 folder-gluers from BOBST. Both high-speed machines – equipped with robotics and fully automated – are currently still put into operation and are installed with an EASYFEEDER 4 pre-feeder and a CARTONPACK 4 automatic packer with an integrated CASE ERECTOR.

In Rinteln, Lower Saxony, state-of-the-art production facilities are being built on an area of more than 6.5 hectares with a revolutionary machine park for a wide variety of packaging solutions in the food segment, especially for frozen products.

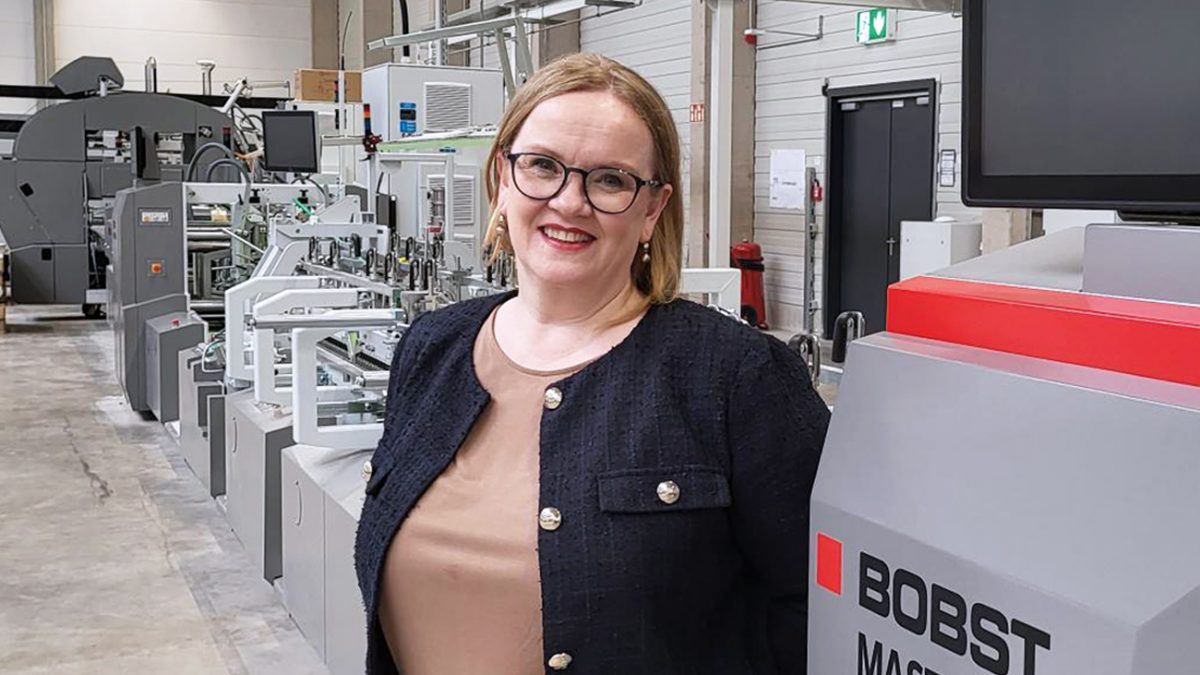

“The Masterfold 75 from BOBST is the best folder-gluer to meet the demands at our new plant in Rinteln,” says Bärbel Wetenkamp, Chief Operating Officer, GPD Foodpackaging. “It has a reputation among packaging manufacturers the world over for reliable high performance. What’s more, the versatility and short setup times support quick production changes – another crucial advantage of the machine.”

Wide Range of Materials

The Masterfold 75 and its Easyfeeder 4 and Cartonpack 4 peripherals reliably work with a wide range of different packaging materials, another important criteria for GPD Foodpackaging. “The plans for our new plant focused on attaining significant savings, in particular in energy and paper consumption, as compared to conventional packaging manufacture. One way to achieve this is by replacing virgin paperboard with recycled paperboard,” explains Wetenkamp. The two Bobst lines in Rinteln will work with blanks of GD2 chromo duplex board at grammages from 200 to 500 gsm.

When it comes to production, GPD Foodpackaging is breaking new ground at this plant in several ways. It uses a web-fed offset printing system with rotary inline die-cutting specially set up for paperboard printing and one of the first such machines in Europe. It works with food-safe, EB-curing ink, and its higher-than-average printing speed provides for impressive productivity.

The tried and true technology of both Bobst folder-gluers earn them their rock-solid position in this innovative and fully automatic production process. Wetenkamp continues, “Customers are impressed with our relying on this high-end technology for processing the blanks of finished packaging.”

The smooth interaction of the Masterfold 75 with its peripheral devices ensures that the plant can count on maximum productivity from an uninterrupted folding and gluing process. The Easyfeeder 4 pre-feeders ensure quick, smooth and consistent delivery of blanks into the feeder of the folder-gluers, preventing production stops. At the end of the gluers, the Cartonpack 4 automatic packers fill shipping boxes with up to 200,000 units of packaging per hour, all while providing GPD Foodpackaging with various packing options. GPD can save the settings of individual production orders in the MATIC control of its folder-gluers and retrieve them at any time for repeat orders, further shortening the setup time of these orders.

Moreover, plant management can access the machine data at any time via Bobst’s productivity apps and use them for analysis and process optimization. “We look forward to working with these high-end machines. They fit right into our revolutionary production process”, adds Henning Diedrich, CEO, GPD Foodpackaging.

“Bobst is championing a drive to transform the packaging industry by making the entire production chain more agile and sustainable,” says Hans Dreistein, Sales Manager, Bobst Meerbusch. “The primary cornerstones are digitization, connectivity, automation, and sustainability. With the new plant in Rinteln, GPD Foodpackaging is taking a big step toward packaging production that is in line with Bobst’s vision of the future.”