When high-speed single pass digital printing was first introduced to the corrugated market a few years ago, Finn MacDonald and his team at Independent II watched closely. MacDonald knew he wanted to offer customers digital printing, but he was not convinced that the existing technology was well-suited to his company’s mix of business. Founded in 2006 in Louisville, Ky., Independent II is a full service sheet plant that MacDonald, who is President, likes to refer to as a brown box and light brand manufacturer. Services include design, manufacturing, warehousing and delivery to customers in the food and beverage, e-commerce, home goods, innovation/technology and manufacturing sectors.

“We understand where our strengths are and where our market is. Our DNA isn’t built around a lot of high-end display or POP work,” MacDonald says. “As those first generation high-end digital printers came out, we would stay connected with that technology and who it was best suited for, but we never felt like it was speaking to us.”

Nonetheless, the company did offer digital printing to its customers through a coalition of partners. It was a way to learn more about digital without having to make a sizeable investment in the equipment.

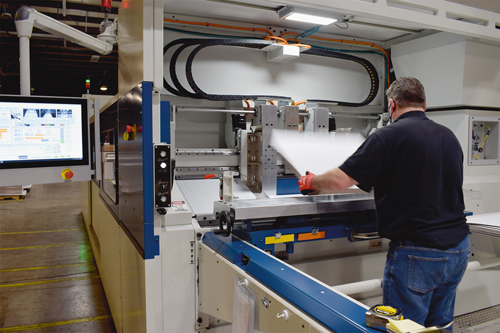

MacDonald found an alternative solution last year when Domino introduced the X630i digital corrugated press. The single pass, flexo caliber machine was installed at the Louisville facility in August and is the first installation in North America. Printing at speeds up to 246 fpm (75m per min), the X630i offers throughput on a small footprint, measuring 10 ft H x 38 ft W x 21 ft D and allows for a wide range of print options. MacDonald says the press is “fundamentally different” from other digital presses for corrugated because it can operate in an industrial production environment, has a relatively small footprint, uses

aqueous inks and includes components from well-known corrugated industry suppliers.

The X630i is based on Domino’s proven Generation 6 ink jet platform, which has nearly 1000 global industrial ink jet installations. The press is ideal for shipping containers, shelf-ready packaging, and displays and features Domino’s i-Tech intelligent Technology for high quality printing. The Domino AQ95 aqueous ink set is Swiss Ordinance and Nestle compliant for food packaging and enables printing on a wide range of uncoated and coated stocks, with no pre-coating primer or bonding agent required. The print resolution is 600 dpi.

Domino has partnered with well-known suppliers, such as Esko for the digital front end, and SUN Automation for the lead edge feeding system. “That was reassuring to us,” MacDonald says. “SUN is in a lot of plants and if you’re getting that sheet through the machine uniformly and consistently without any issues – good in is good out – then that’s a great start and something that we thought made this a strong partnership. The SUN experience in the machine meant that important element of transfer was well-known and had a good DNA behind it.”

The servo driven continuous bottom feeding system provides automated setup for sheet sizes, caliper and vacuum assist. It can store jobs and sheet sizes for quick setup and can feed E- to B/C-flute.

Another feature on the X630i that MacDonald likes is the range in blank sizes that the press can handle, which he says is more accommodating for Independent II’s downstream converting machines. “If you’re running single outs on a flexo folder-gluer, you can start single out at the digital press. The ability of the press to be able to handle that size blank allows us to put the print performance in digitally and then single pass it through the flexo folder-gluer to add the diecut performance and join the box. We don’t have to go to a diecutter and break it down and then take it to a specialty gluer to put it back together,” he explains. “That’s really an area of opportunity that is under-addressed in the market. Having a wider range of dimensional blank sizes go through the Domino press means less work downstream.”

The print area on a 63- x 118-inch blank is 53- x 118-inch. “That’s a great size blank for a 66-inch diecutter or a 37-inch to 66-inch flexo,” he says.

Domino is currently working on a stacker that will be installed on the press later this year.

‘Responsive Packaging’

This investment provides a competitive advantage and strengthens Independent II’s strategy to offer ‘responsive packaging,’ a term that MacDonald uses to describe the packaging needed for these tumultuous and disruptive times. With everything changing daily, the press offers customers a cost-effective way to quickly change their branding and messaging as needed.

“This last year has shown us that if it can be turned upside down or changed drastically, it can happen. If disruption happens we’re going to be in a unique position to help our customers through it,” MacDonald says. “Responsive packaging is a very poetic term that you can sell to and that resonates with consumers. Our Domino press can help us have that responsive conversation with our customers and with their consumers. I really think that’s such a great opportunity.”

The press is expected to open up new business and new markets for inside/outside printing, customization, variability and a wider color pallet. And then there is the opportunity to run everyday orders, the type of business that funnels through Independent II on a daily basis. “There is this neat area to capitalize on in the everyday world. So much of our life is made up of everyday things and I really think we are in a position to be more dynamic in the everyday space,” MacDonald says. “The space above us is well-known. That’s high-end premium, but when you get down to where so many of us are impacted with our packaging, that’s this everyday level.”

While the press is suitable for short and medium runs, MacDonald says order sizes at Independent II vary, depending on the job. “We’ve run 10,000, 15,000 or 30,000 piece orders. If someone has a 50 or 100 piece order that’s going to put them into the retail space for the first time successfully or get to an influencer or to a doorstep with that little bit of surprise, then we want to create time on the machine to do that as well.”

He mentions one such opportunity where a customer was purchasing about 7000 mostly unprinted kraft RSCs and then hand applying two sets of labels to four different SKUs. Digital printing provided a more efficient solution with expanded multi-color graphics. “At one time when labor was readily available and less expensive and getting people into your plant wasn’t a public safety concern and you had more space to store label stock it made sense. Now this customer wants other options that would remove hand labor and the investment in stored label stock that required a minimum order,” he says.

Digital Journey

Space on Independent II’s production floor was limited to a point where there was not adequate room to add additional print units on existing machines. The Domino X630i is located in a designated area in the warehouse known as the “Digital Center.” The 25,000-sq-ft space includes the Domino x630i, meeting space, a prepress office, and production and WIP. MacDonald jokes that his digital journey begins every day with a one-quarter mile walk from his office to the press. He says the center is an “oasis” to get work done. “We can more clearly lay out our raw material, and we can better prepare our work in process.

“This digital press can bring multi-color work to any of our existing machines, from Solarco box makers to Baysek flatbed diecutters to our BWP flexo folder-gluers and rotary diecutters,” he says. “We can bring all the value and pluses of digital to any one of our existing converting centers without having to make significant investments in those machines to bump up to four-color process.”

MacDonald is calculating the X630i will produce operational savings as well as generate new revenue. “If we can get more jobs produced daily – we win. If we can reduce our speed to customer – we win. If consistency improves and managing the print elements of pre-press decreases – we win. When our customers initiate or convert to digital – we win.”